Machinemonitor® and SERGI join forces to introduce the Transformer Protector™ rapid depressurisation system in Australia and New Zealand

machinemonitor®, the Australian specialist in high‑voltage asset monitoring and maintenance, and SERGI, the French pioneer of anti‑explosion solutions for transformers, announce an exclusive agency agreement for Australia and New Zealand.

Through this partnership they will locally market the Transformer Protector™ (TP), a mechanical fast depressurisation system designed to prevent transformer explosions and fires.

Dr Jon Pemberton, Director of machinemonitor® said:

“Grid resilience is a national priority. This partnership allows us to provide our customers and communities with a level of protection that significantly reduces the risk of transformer explosions and fires. Integrating the Transformer Protector™ into new renewable projects and existing installations is a logical step for the safety and reliability of our electrical economy.”

Transformers are critical components of electrical transmission and distribution networks, yet they remain vulnerable to internal faults. An academic study on transformer reliability recorded 730 transformer explosions in a single year in the United States, with significant economic and environmental consequences.

As the deployment of renewable energy accelerates in Australia and New Zealand, the transformer fleet will grow markedly—from large 500 MVA units at transmission hubs to thousands of 4 MVA units at solar farms. Preventing explosions and limiting fire propagation is therefore crucial for network security and for the protection of communities.

Francisco Dutra, Key Account Manager at SERGI said:

“We are delighted to team up with machinemonitor®, whose field expertise and nationwide presence in Australia and New Zealand perfectly complement our technology. Together, we will implement a fast depressurisation system proven in high‑voltage tests and installed on thousands of transformers worldwide.”

A proven and recognised solution

Lawrie Cleary, Transformer Technical Lead at machinemonitor®, said:

“Monitoring the condition of transformers reduces risk, but it cannot prevent all internal faults. The Transformer Protector™ provides a passive layer of protection that prevents tank rupture and eliminates oil spillage, limiting fire damage—exactly what renewable energy substations, urban networks and industry need.”

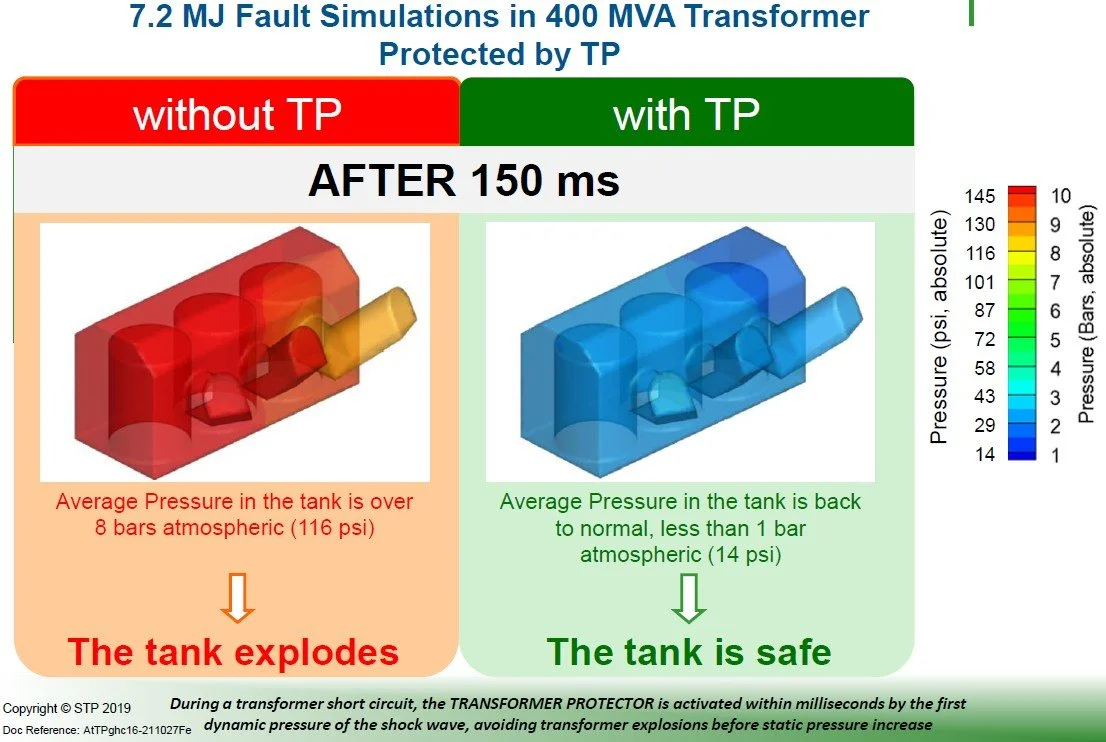

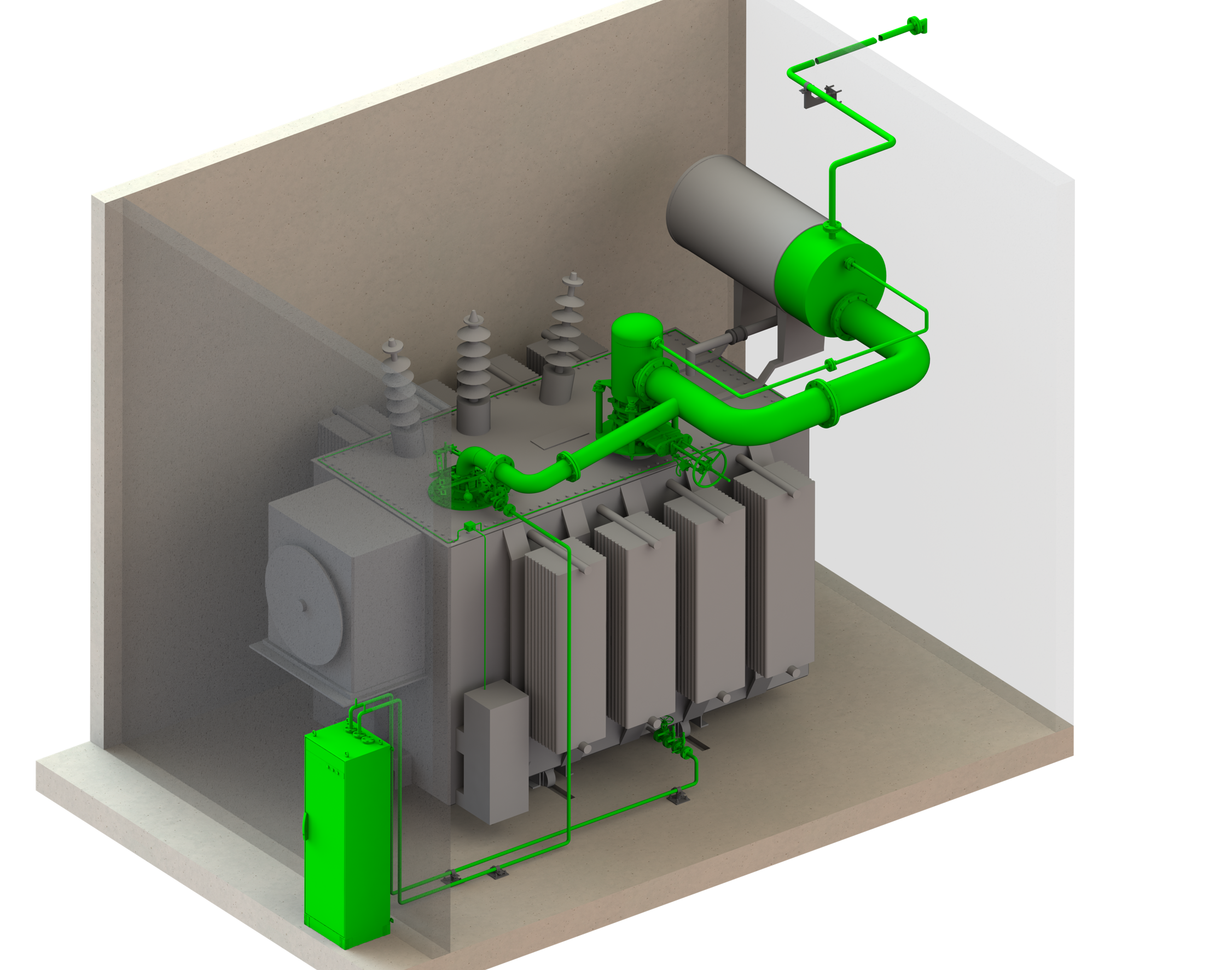

The Transformer Protector™ is a passive system that senses the dynamic pressure peak generated by an internal arc fault and instantly depressurises the transformer oil, thus avoiding tank rupture. Acting within milliseconds—consistent with the NFPA 850 definition of a fast depressurisation system—the TP directs the oil‑gas mixture through a designed rupture disc into an oil and gas separation tank, where the oil is collected and retained while the gases are safely vented away.

Since the transformer tank does not burst, there is no oil spillage, and the entire oil volume remains within the TP system. After depressurisation, an inert gas may optionally be injected to cool the unit and prepare it for maintenance; however, this nitrogen injection is not critical for preventing explosions, but mandatory to prevent secondary fire. Unlike electronic devices, the TP contains no sensors or software and is therefore immune to cyberattacks. It can be installed on new or existing oil‑filled transformers ranging from 0.1 MVA to more than 1 000 MVA.

An established presence in Australia

Even before this new agency agreement, SERGI already had references on Australian soil. For example, the Wallerawang thermal power station, operated by Delta Electricity, is equipped with a SERGI protection system for a 585 MVA transformer. Likewise, following a 2011 incident, Eraring Energy returned its Unit 2 generator transformer to service with Sergi Safety Devices. These achievements demonstrate that the rapid depressurisation solution is already proven and accepted by critical infrastructure operators in Australia.

Why it matters for Australia and New Zealand

Jon Pemberton and Francisco Dutra shake over the SERGI and machinemonitor partnership

Public safety and network integrity: by preventing explosions and fires, the TP protects adjacent equipment, workers and communities, and reduces outage durations.

Compatibility with renewable energy zones: large wind and solar platforms planned in the Renewable Energy Zones (REZ) will concentrate high‑value transformers. The TP is tailored to this risk profile by acting in the first milliseconds.

Simplicity and reliability: fully mechanical activation with no sensors or external power supply; passive operation requiring no sophisticated maintenance.

Resilience and environmental protection: because the TP depressurises the transformer through a dedicated discharge set and collects the oil in a separation tank, there is no release of oil and emissions are minimised. This passive action strengthens the resilience of critical infrastructure by avoiding cascade damage and ensuring rapid restoration of service.

Compliance with standards and cyber‑resilience: Australian standards for transformer protection favour rapid tripping. The Protection and Control of Supply Transformers standard (TasNetworks, 2024) requires low‑impedance differential protection and notes that it must operate rapidly even during partial saturation of associated current transformers. The Ausgrid NS178 standard provides for duplicate (biased) differential protection and mandates mechanical devices such as Buchholz relays and oil surge detectors for each transformer. These mechanical devices act when gas or oil accumulates and provide an additional layer of safety, but experiments show that gas‑accumulation relays have high sensitivity yet insufficient speediness. The TP intervenes even earlier by detecting the dynamic pressure peak, offering a complementary and faster response that aligns with the rapid‑tripping requirements of these standards.

Protection against cyberthreats: digital relays providing rapid differential protection rely on microprocessors and communication protocols. Scientific studies point out that this connectivity introduces cybersecurity risks: digital protections may be targeted by malicious attacks leading to cascading failures. Recent vulnerability disclosures on protection relays have shown that adversaries can disable protection functions or take control of the device by exploiting software flaws. In contrast, SERGI’s Transformer Protector™ is an entirely mechanical device with no programmable logic, making it immune to cyberattacks while triggering depressurisation in mere milliseconds.

Find out more at our upcoming Webinar Event

video shows SERGI TP - Transformer Protector™ (TP), a mechanical fast depressurisation system designed to prevent transformer explosions and fires.

About the partners

machinemonitor®

Founded in 1999, machinemonitor® is the leader in Australia and New Zealand in the monitoring and maintenance of high‑voltage electrical assets, having conducted close to 11,000 tests on nearly 800 machines. Their expertise includes traditional power & renewable energy, resources & mining and industrial sectors.

About SERGI

Created in France in 1952 by Electricité de France, SERGI is a pioneer of solutions for preventing transformer explosions and fires. The Transformer Protector™ has been a benchmark for more than two decades and is installed on over 4,000 transformers across more than 85 countries. Complying with the recommendations of NFPA 850, the TP enhances the safety and resilience of power grids worldwide.